Worldwide patents in power electronic equipment (Sintering Press - Silver Sintering/Copper Sintering and Scanning Acoustic Microscopy).

Wide range of patented die attach related equipment for the Power Electronic field.

Pressure sintering (silver sintering or in the next future copper sintering too) is a die attach heat treatment process applied to a powdered material in order to give it higher strength, integrity and conductivity.

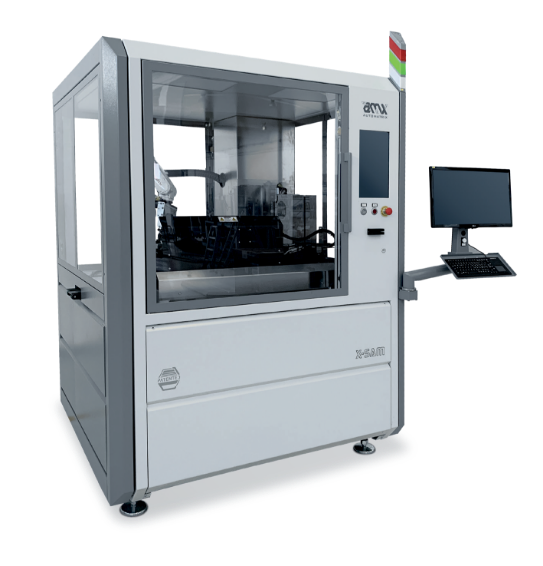

The InLine X-SAM is a new system designed for quality control in power electronics industries. A non-destructive inspection able to simplify the manufacturing process.

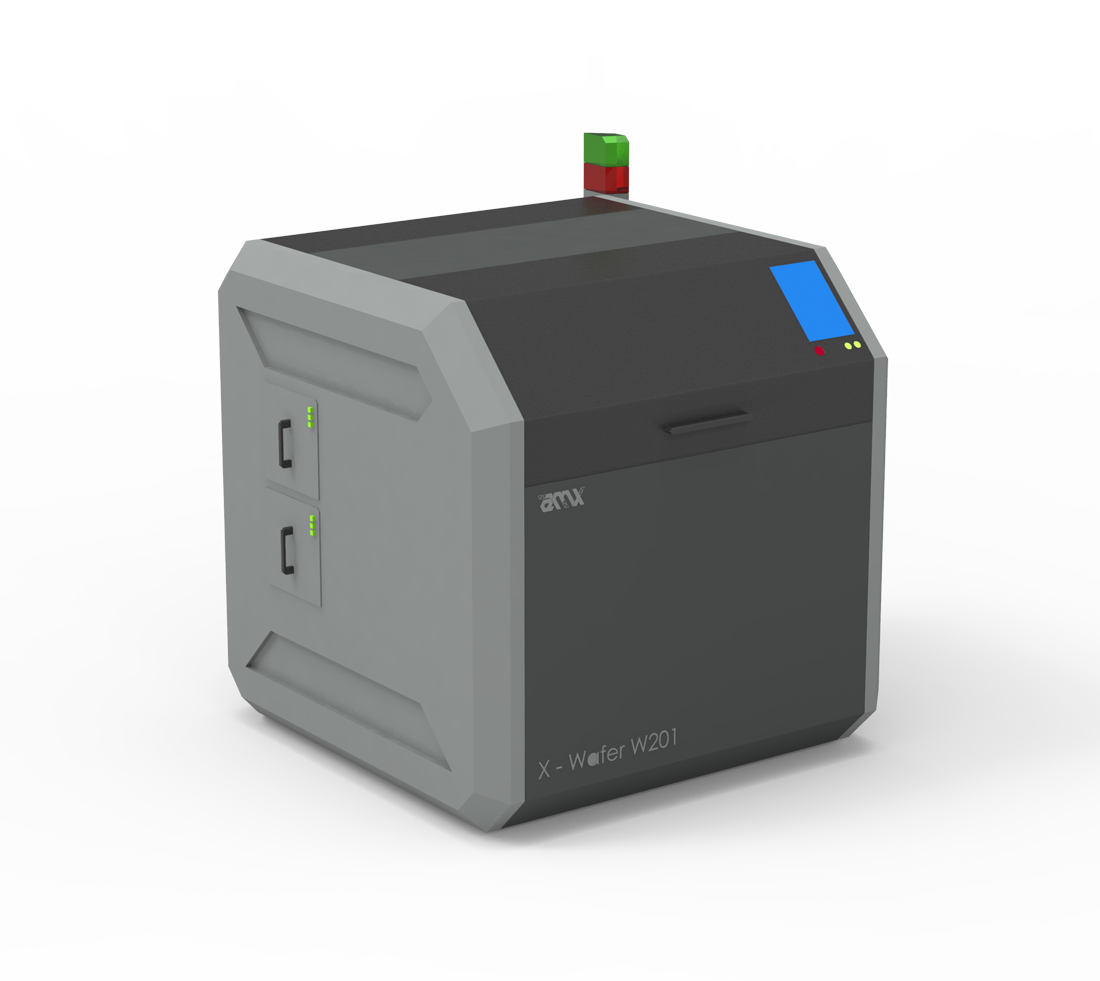

P200 W Series is a full-automatic flat press system able to laminate wafers of different dimensions and thickness for high performance die attach applications.

AMX Automatrix worldwide patented a unique sintering tool for its sintering press, the ‘Micro-Punch’ able to press individually and with a dedicated pressure every single component on the substrate.

Discover more