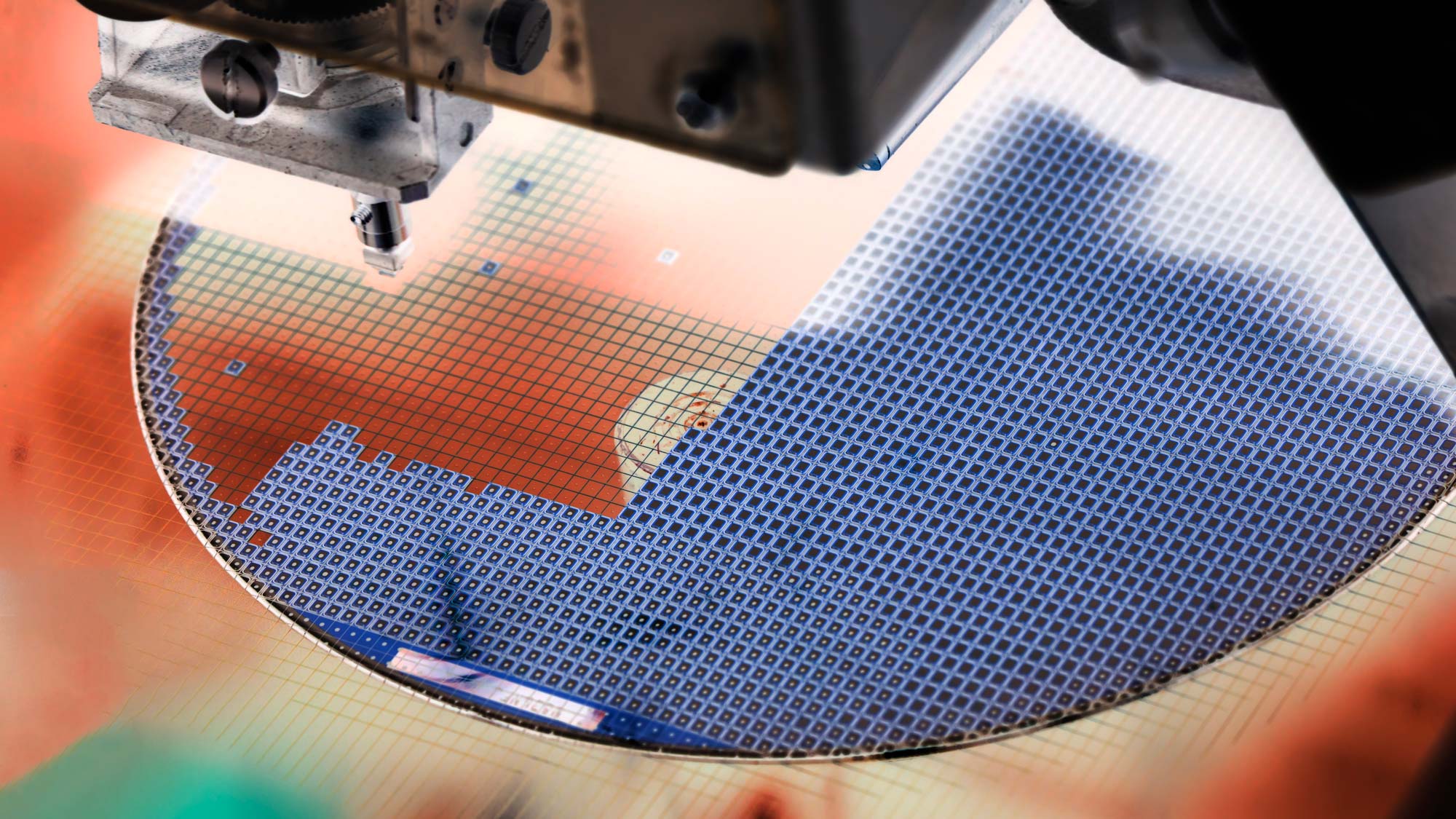

Core application involving the bonding of SiC/IGBT/MOSFET dies to substrates (DBC or AMB). It supports the simultaneous sintering of diverse components (e.g., NTC thermistors, IGBR resistors, clips, spacers, and pillars) within a single production cycle.