Years of experience have enabled our specialist to develop refined skills in managing these applications.

Thanks to this know-how, AMX is able to provide comprehensive support throughout the entire assembly process.

Main process workflow is:

-

Plasma cleaning of substrates and die backside

-

Stencil printing on substrate with custom stencil (3D stencil printing available)

-

Drying in a nitrogen (N₂) oven

-

Pick and place of dies over paste using hot tacking process to keep the dies in position

-

Sintering in N₂ atmosphere using our Micropunch system or flat tool with buffer materials

-

Scanning Acoustic Microscopy (SAM) analysis

-

Shear test analysis

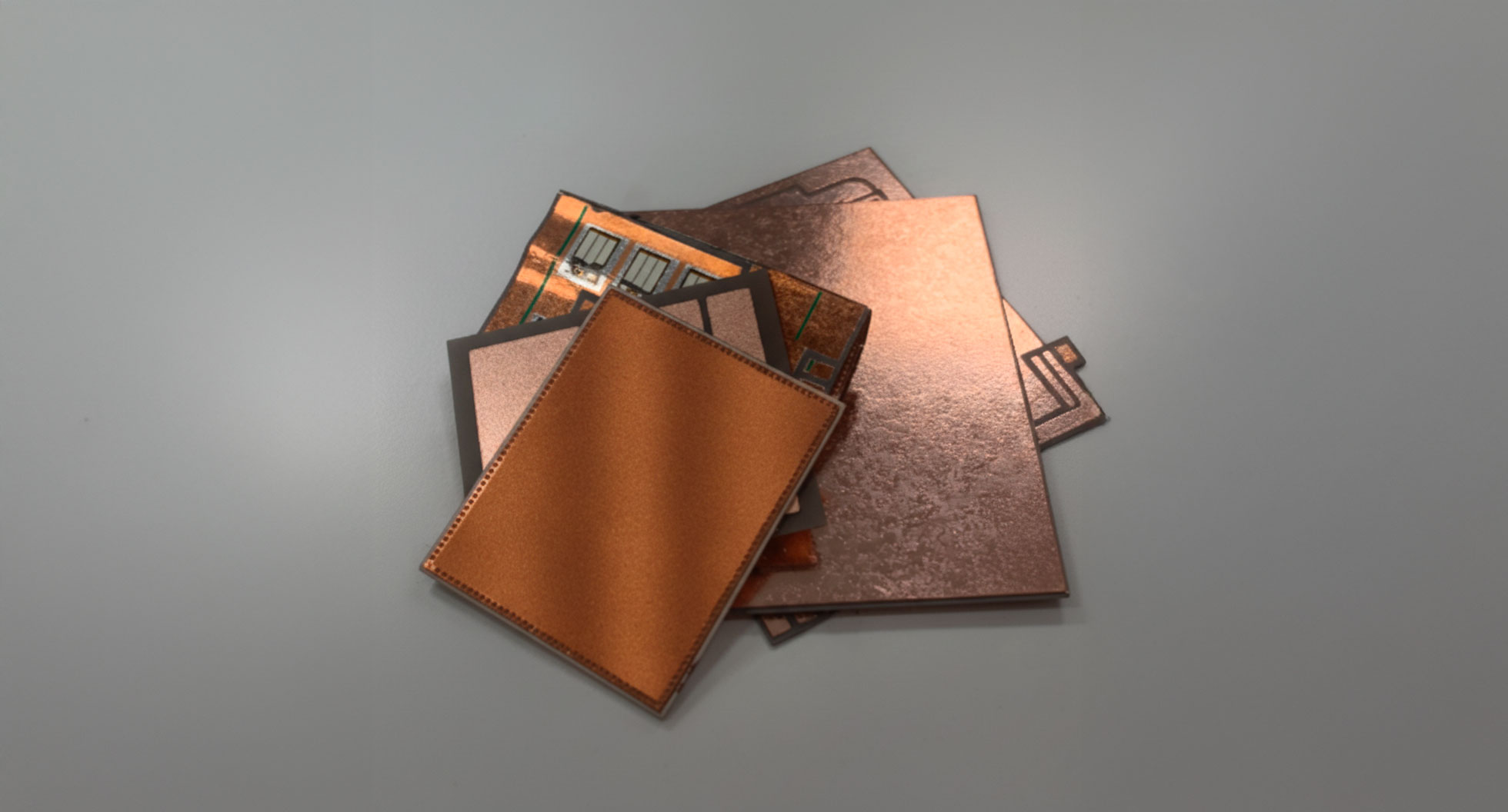

AMX is also experienced in assembly and sintering of:

-

Spacers

-

Gate resistors

-

NTC

-

Metallized piezoelectric sensors

-

Lead frames

Contact us for specific process development and testing support.