Wide range of patented die attach related equipment for the Power Electronic field.

Pressure sintering (silver sintering or in the next future copper sintering too) is a die attach heat treatment process applied to a powdered material in order to give it higher strength, integrity and conductivity.

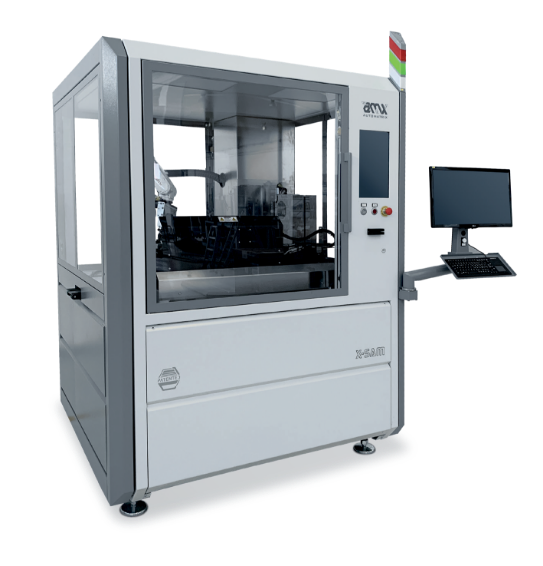

The InLine X-SAM is a new system designed for quality control in power electronics industries. A non-destructive inspection able to simplify the manufacturing process.

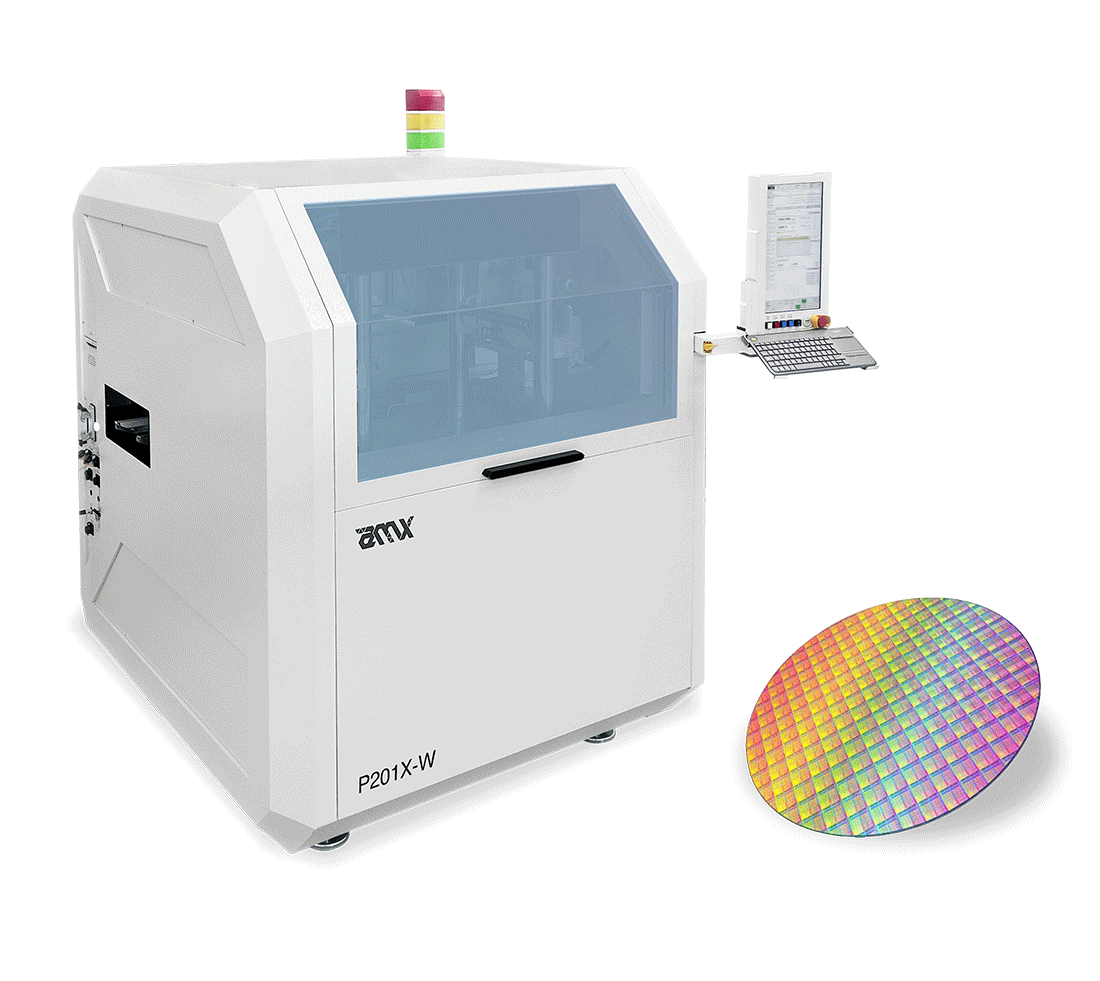

P200 W Series is a full-automatic flat press system able to laminate wafers of different dimensions and thickness for high performance die attach applications.

AMX Automatrix worldwide patented a unique sintering tool for its sintering press, the ‘Micro-Punch’ able to press individually and with a dedicated pressure every single component on the substrate.

Discover more