Tool for R&D, Prototyping, Materials Research, and Education in Power Electronics

The power electronics industry is undergoing a rapid evolution, driven by the increasing demand for high power density, efficiency, and reliability in sectors like electric vehicles (EV/HEV), renewable energy, data centers and telecommunications. In this landscape, pressure sintering has emerged as the most reliable joining technology, surpassing traditional methods like soldering due to its superior performance at high temperatures. For universities, research institutes, and corporate R&D departments, access to flexible, precise, and user-friendly equipment is critical for studying new materials, developing prototypes, and training the next generation of engineers. The AMX Automatrix X-Sinter P50 series is specifically designed to meet these needs, offering a range of manual and semi-automatic presses ideal for laboratory and clean room environments.The Critical Role of Pressure Sintering: Technical Advantages

Pressure sintering is a heat treatment process that applies controlled heat and pressure to a powdered material—typically silver (Ag) or copper (Cu) paste—to create high-strength, high-integrity joints with superior conductivity. Unlike soldering, which involves melting, sintering is a solid-state atomic diffusion process that occurs below the material's melting point but yields a joint with a much higher re-melting temperature, often exceeding 400°C. This makes it ideal for bonding wide bandgap (WBG) semiconductors like Silicon Carbide (SiC) and Gallium Nitride (GaN) but also new silicon IGBT (Si) generation, which operate at elevated temperatures and higher power densities than traditional devices.The key technical advantages of pressure sintering include:

• Superior Thermal and Electrical Performance: Silver (Ag) sintering provides exceptional thermal conductivity, typically >300 W/(m·K), and low electrical resistivity of ~2 µΩ·cm. This is a significant improvement over traditional solders, which can have thermal conductivities as low as 70 W/(m·K). Copper (Cu) offers similar performance at a lower material cost but requires an inert atmosphere to prevent oxidation, a capability built into AMX machines.

• Enhanced Reliability and Lifetime: Sintered joints demonstrate a lifetime up to 100 times longer than solder interconnects in power cycling tests. Temperature shock tests show solder joints reaching their limits around 150°C, while sintered interconnects can handle much higher temperatures. This makes them essential for automotive applications which demand long-term reliability under harsh conditions.

• Reduced Porosity and Defect Prevention: Applying external pressure during sintering is crucial for creating a dense, reliable bond. The process significantly reduces the porosity of the bond layer, typically to less than 10%, compared to over 25% for pressure less sintering. This "densification" minimizes voids, which are a primary cause of delamination, cracking, and eventual package failure.

• Improved Mechanical Strength: Scientific studies have quantified the direct relationship between pressure and joint strength. Experimental results show that increasing sintering pressure on a nano-Ag film from 5 MPa to 15 MPa significantly improves the shear strength from <40.0 MPa to >~70.0 MPa. This pressure increase also facilitates a fracture mode transformation from brittle to ductile, enhancing the joint's robustness. The AMX P50 series is capable of applying up to 40 MPa, enabling researchers to explore this full range of mechanical properties.

The P50 Series: Designed for Flexibility in Research and Development

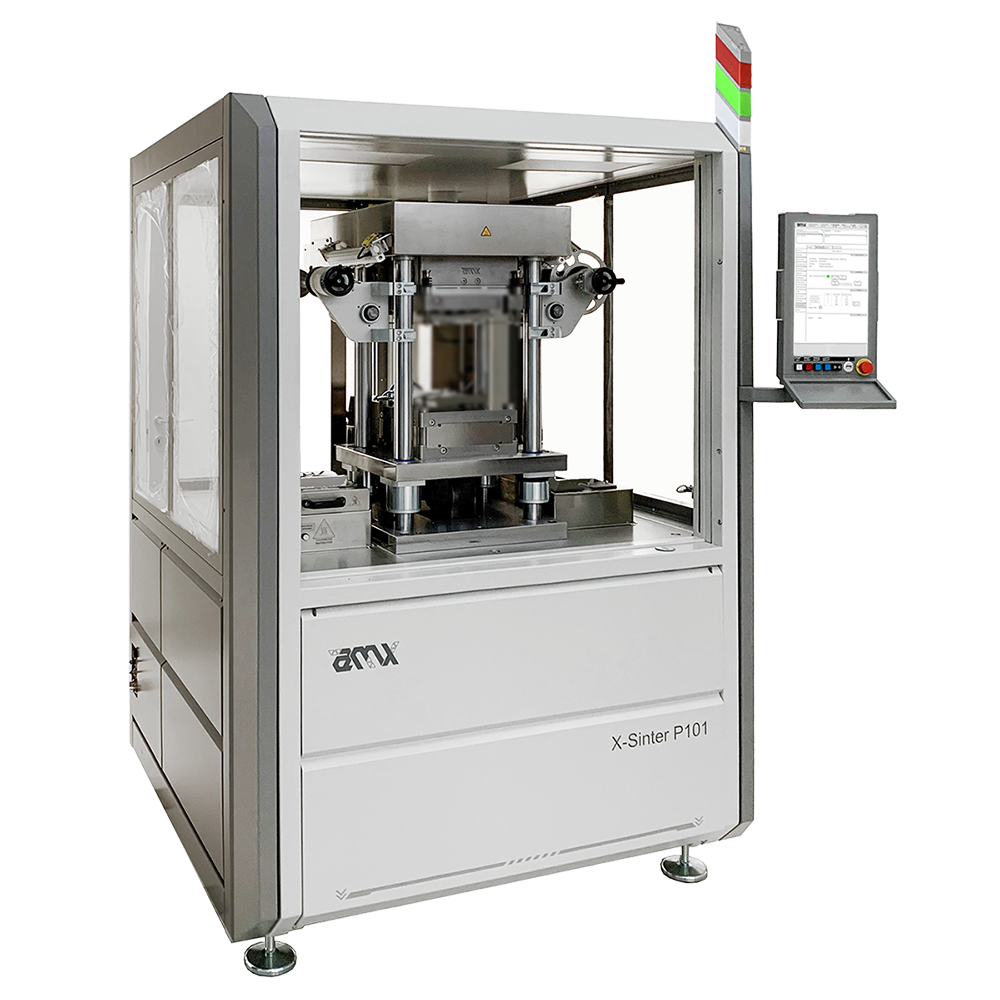

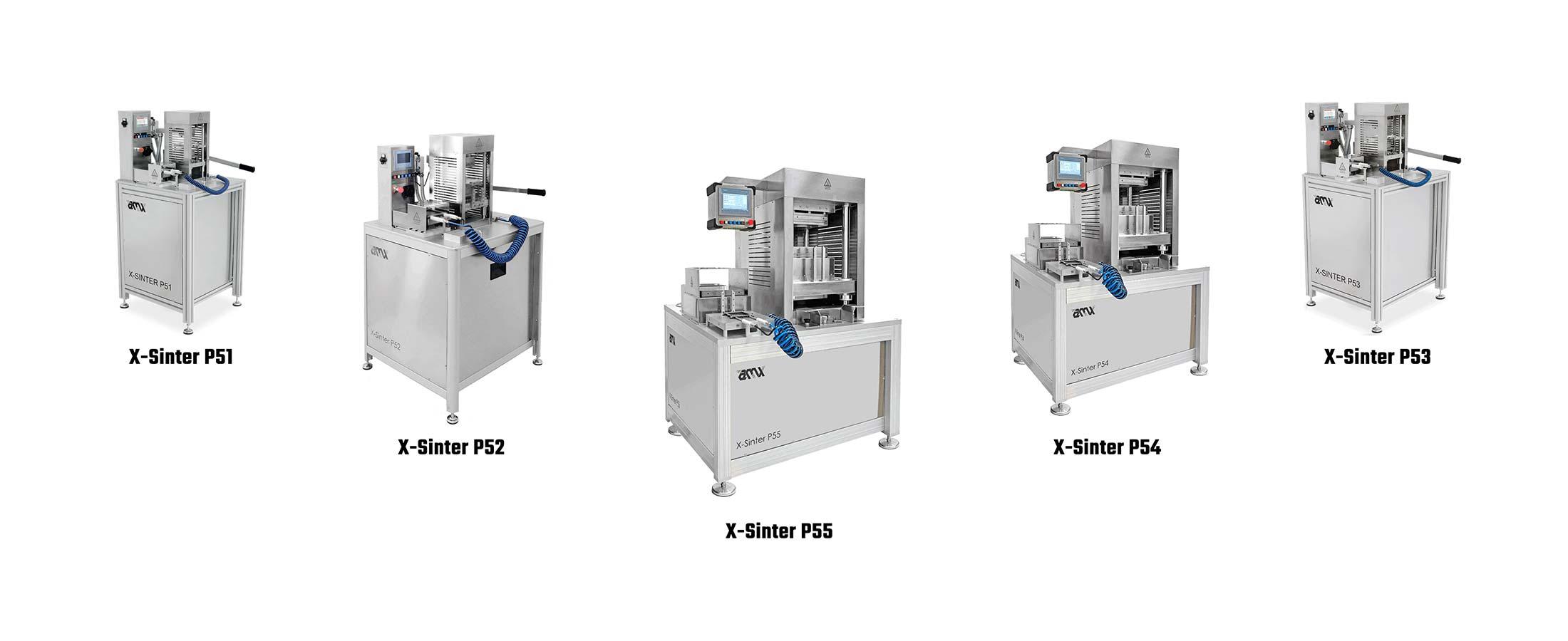

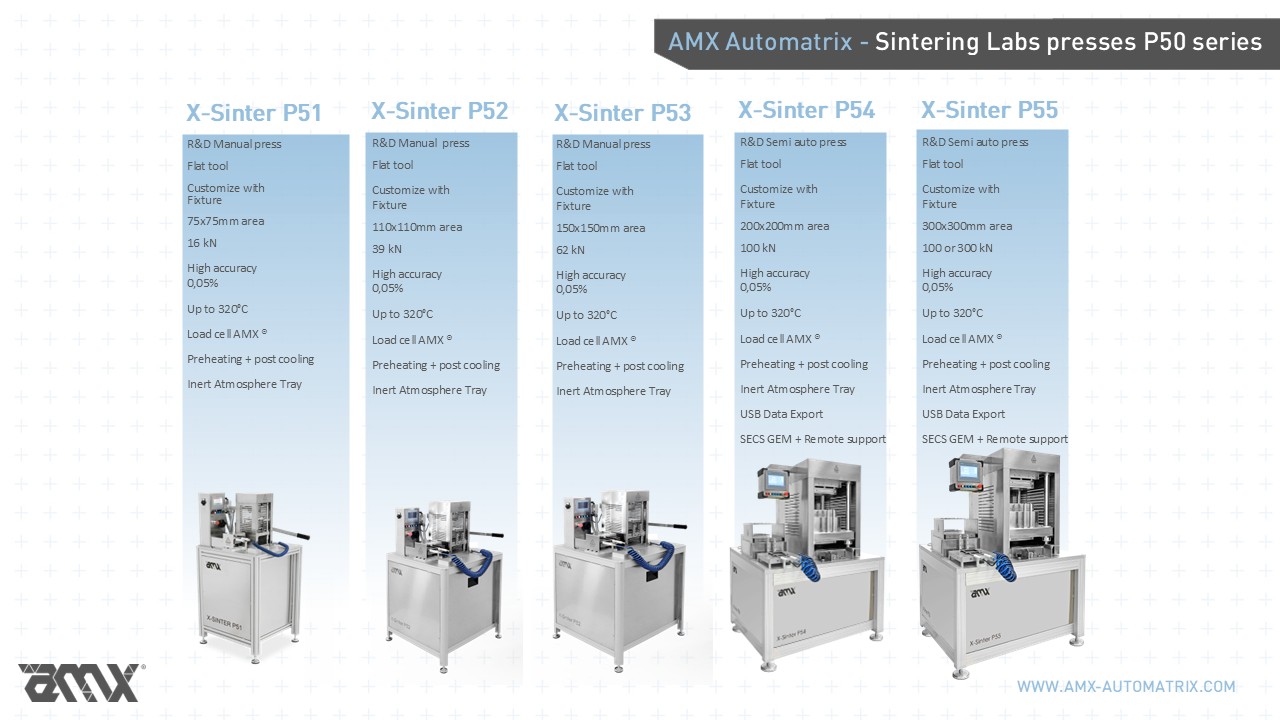

The AMX X-Sinter P50 series is a comprehensive range of manual (P51, P52, P53) and semi-automatic (P54, P55) presses designed for R&D, prototyping, and quality inspection. These compact machines are perfectly suited for lab and clean room environments but are engineered to deliver the same high performance as inline production units, reaching pressures up to 40 MPa and temperatures up to 320°C with high accuracyEase of Use for Academic and Research Settings

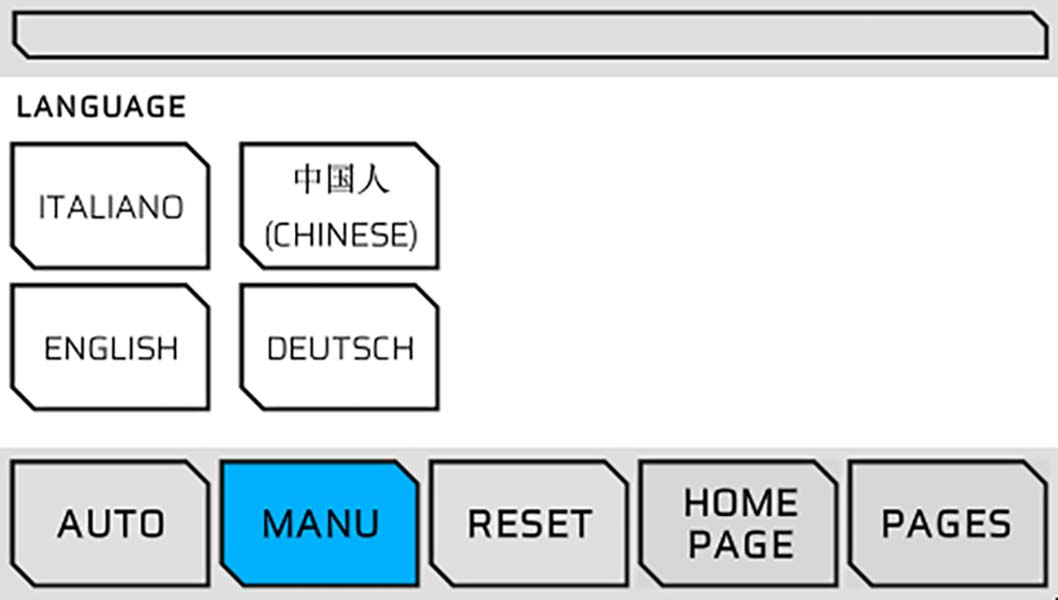

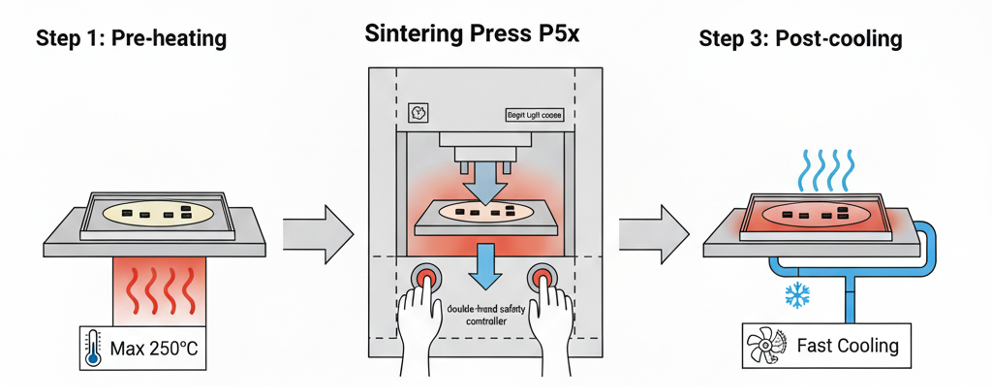

A key feature of the P50 series is its user-friendliness, making it an excellent tool for university courses and research labs. The machines feature an intuitive, multi-language interface that simplifies operation. The manual process cycle is straightforward: an operator loads a sample into the pre-heating area, manually moves it to the sintering tool to apply the thermo-mechanical cycle, and finally transfers it to a cooling area. The semi-automatic P54 and P55 models further streamline this with automatic clamping and allow process data (pressure, temperature profiles) to be easily exported via USB or FTP server for complete traceability and analysis.The X-Sinter P50 Series: A Detailed Look at the R&D Platform for Pressure Sintering

The AMX Automatrix X-Sinter P50 series is a comprehensive range of manual and semi-automatic presses specifically engineered for research and development (R&D), prototyping, and quality inspection in laboratory and clean room environments. Designed as the perfect entry point into silver (Ag) or copper (Cu) sintering, these machines offer high accuracy and reliability, capable of replicating the same pressure and temperature conditions found in full inline production units. The series includes manual models (P51, P52, P53) and semi-automatic models (P54, P55), providing a scalable solution for academic research, materials science, and pre-production prototyping.Technical Features and Specifications

The P50 series is built to provide precise control over the key parameters of the sintering process: time, pressure, temperature, and atmosphere. While each model has a different footprint and force capability, they share core high-performance features.

• Maximum Sintering Pressure: All models in the series can achieve a maximum sintering pressure of 40 MPa, which is the industrial standard for achieving high-density, low-porosity joints. This pressure range is critical for enhancing the shear strength and reliability of the bond.

• Maximum Temperature: The sintering tool, which consists of both upper and lower heating plates, can reach temperatures up to 320°C or 350°C, depending on the model and configuration. This temperature range is suitable for processing most commercial Ag and Cu sinter pastes.

• Force Application and Accuracy: The clamping force varies across the series, from 16 kN for the P51 up to 300 kN for the P55. This force is measured by a proprietary AMX® load cell system that ensures high accuracy. This accuracy allows for repeatable experiments and reliable quality control.

• Working Area: The tool size scales with the model, from 75 x 75 mm for the P51 to a large 300 x 300 mm for the P55, making the larger models suitable for large area sintering of entire mastercards or frames.

• Tooling: The standard configuration is a flat plate sintering tool, which is highly versatile for R&D. These tools can be easily customized with dedicated fixtures to accommodate specific substrates or component geometries.

| Feature | X-Sinter P51 | X-Sinter P52 | X-Sinter P53 |

X-Sinter P54 (Semi-auto) |

X-SinterP55 (Semi-auto) |

|---|---|---|---|---|---|

| Working Area | 75 x 75 mm | 110 x 110 mm | 150 x 150 mm | 200 x 200 mm | 300 x 300 mm |

| Max Clamping Force | 16 kN | 39 kN | 62 kN | 100 kN | 300 kN |

| Max Sinter Pressure | 40 MPa | 40 MPa | 40 MPa | 40 MPa | 40 MPa |

| Max Temperature | 320°C / 350°C | 320°C / 350°C | 320°C / 350°C | 320°C / 350°C | 320°C / 350°C |

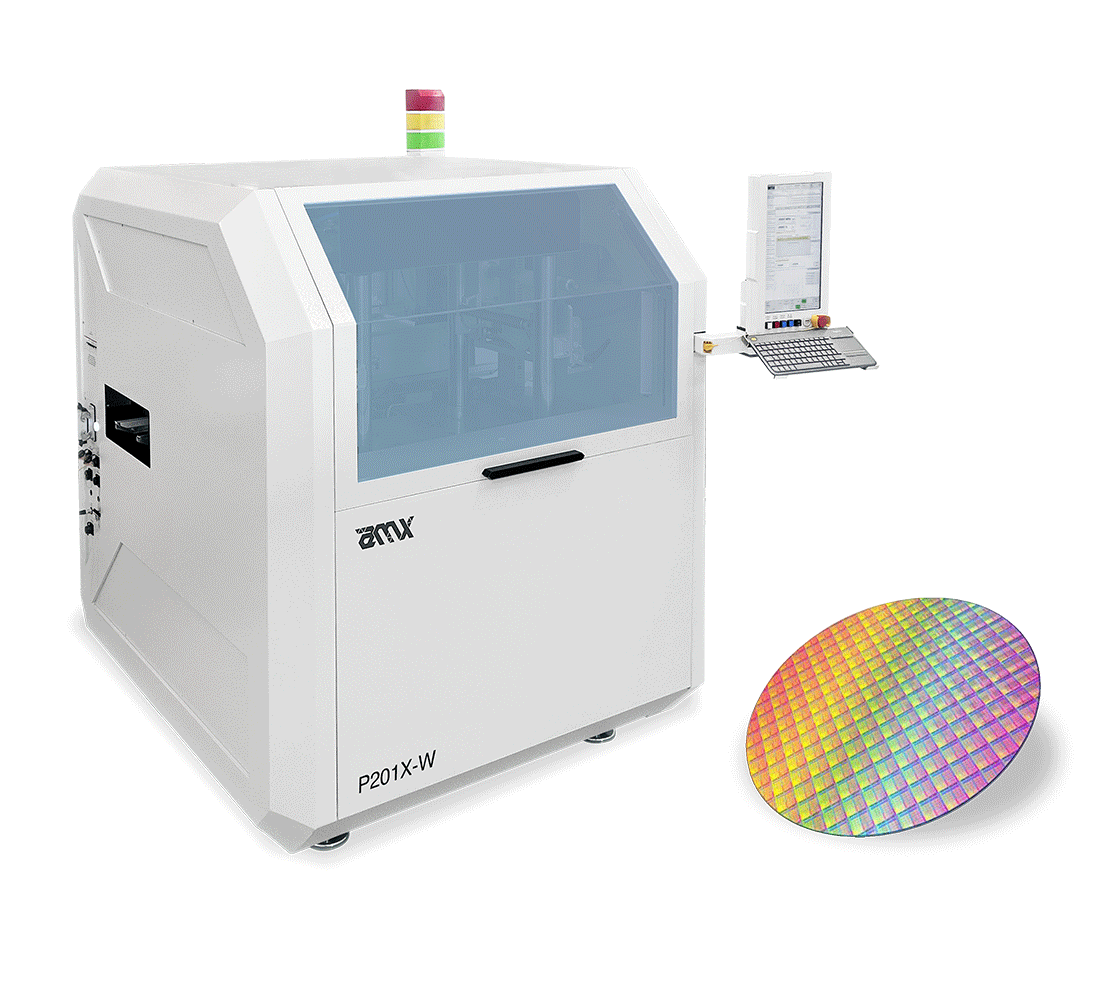

| Wafer Processing | No | No | No | No | Yes, up to 12" (Wafer processes including D2W, lamination & W2W sintering) |

| Data Traceability | No (manual) | No (manual) | No (manual) | Database, DMC scanner, USB/FTP export | Database, DMC scanner, USB/FTP export |

| MES | - | SecsGem + MES data storage | SecsGem + MES data storage |

Atmosphere Control: Enabling Silver and Copper Sintering

A crucial feature of the P50 series is its capability to operate under a controlled atmosphere, making it ready for both Ag and the next generation of Cu sintering. Copper is highly susceptible to oxidation, which can prevent the formation of a reliable bond. The P50 series addresses this with an Inert Atmosphere Tray system.This system allows the entire process—pre-heating, sintering, and post-cooling—to be performed without exposure to oxygen. The available controlled atmospheres include Nitrogen (N2), forming gas, and vacuum, with other options available on request. The ability to create an inert environment is essential for sintering on bare copper substrates (like DBC) or for using copper pastes, as it prevents the formation of performance-degrading oxides (2Cu + O2 -> 2CuO). Even for silver sintering, an inert atmosphere can prevent oxidation on copper elements within the package, such as clips or lead frames, ensuring no cosmetic or functional defects.

Operational Workflow and Ease of Use

The P50 series is designed for ease of use, making it ideal for operators and researchers new to the technology. The operational workflow for the manual presses (P51, P52, P53) is straightforward and allows for direct hands-on control.Step 1: Pre-heating: The operator manually places the workpiece carrier (tray) containing the substrate and die onto the pre-heating area. This stage can be configured to reach temperatures up to 250°C (or 200°C in some models).

Step 2: Sintering: The operator manually slides the tray from the pre-heating area into the sintering area under the main press tool. Force Application: For manual presses, the operator uses a lever to apply pressure. For the semi-automatic P54 and P55, clamping is automatic and initiated via a double-hand safety controller for operator safety. The machine then executes the pre-programmed pressure and temperature

Step 3: Post-cooling: After the sintering cycle is complete, the operator unloads the unit and moves it to the post-cooling area. In the smaller models, this is a metal plate for natural air cooling, while the P54 and P55 feature a more advanced liquid cooling circuit for faster temperature reduction.

The machines are managed through an intuitive, multi-language touchscreen interface (Simatic HMI) that allows operators to set and save recipes, monitor process parameters, and manage user access levels. On the semi-automatic P54 and P55, all process curves (temperature, pressure) can be easily exported via USB or FTP server in formats like .CSV, allowing for full data traceability, which is essential for academic research and industrial quality control. Additionally, these models can be equipped with external thermocouple connections (up to 4) for precise temperature monitoring directly on the sample.

Applications and Examples with P50 Models

1. Prototyping and Materials Science on AMB & DBC Substrates (P51, P52) The manual presses X-Sinter P51 and P52 are ideal platforms for fundamental research and small-scale prototyping. Their compact size and precise control over pressure and temperature make them perfect for:• Evaluating Sintering Pastes: Researchers can test various formulations of Ag or Cu pastes, which forms strong bonds on bare copper DBC substrates at temperatures as low as 250°C and pressures under 10 MPa. The P50 series allows for precise replication of these conditions to verify properties like shear strength, which can exceed 50 MPa.

• Studying Material Interfaces: The ability to sinter on different substrates is crucial. The P51 and P52, with customizable fixtures, can be used to bond Si or SiC dies onto common power electronic substrates like DBC (Direct Bonded Copper) and Si3N4 AMB (Active Metal Brazed).

• University Courses in Power Electronics: These machines serve as invaluable hands-on educational tools for students in electrical engineering and materials science programs. They allow for practical experimentation with cutting-edge die-attach technologies, bridging the gap between theory and industrial application. AMX actively collaborates with research institutes worldwide, making their equipment accessible for academic studies.

2. Large Area and Wafer-Level Sintering (P54, P55) The semi-automatic X-Sinter P54 and P55 models offer larger tool areas and higher clamping forces, extending capabilities to more advanced R&D applications.

• Large Area Sintering: With tool areas of up to 200x200 mm (P54) and 300x300 mm (P55), these presses can sinter entire mastercards, frames, or attach already molded packages onto heatsinks. This is critical for improving thermal management at the module level. They can also handle thicker components by modulating the clamping stroke.

• Wafer-to-Wafer Sintering and Lamination: The P55 model is specifically equipped with a wafer-level tool, enabling it to process entire wafers up to 12 inches in diameter. This capability supports advanced research in 3D packaging, wafer lamination, and other next-generation integration technologies.

Conclusion: A Versatile Platform for Innovation

As the power electronics industry pushes towards higher power densities and operating temperatures with SiC and GaN devices, pressure sintering is an indispensable technology. The AMX Automatrix X-Sinter P50 series provides an accessible, precise, and highly versatile platform for exploring and advancing this technology. From fundamental materials studies on the P51 and P52 to advanced large-area and wafer-level prototyping with the P54 and P55, these machines are more than just tools—they are catalysts for innovation. They empower universities and research centers to conduct cutting-edge studies, develop next-generation power modules, and equip students with the practical skills needed to shape the future of the Green Revolution.References and Recommended Bibliography

Toepper M., Huttler M, Fraunhofer IZM (2021 April 20). High reliable solder and sintering technology.

Liu, Y., Zhang, H., Wang, L., Fan, X., Zhang, G., & Sun, F. (2018). Effect of Sintering Pressure on the Porosity and the Shear Strength of the Pressure-Assisted Silver Sintering Bonding. IEEE Transactions on Device and Materials Reliability, 18(2), 240-246. AMX Automatrix. (2024).

Ag/Cu Pressure Sintering Technology for Power Semiconductors. Greci, A., Ugolini, F., Bazoli, V. (2022).

Ag/Cu Pressure Sintering Technology for Power Semiconductors mass Production. AMX Automatrix. AMX Automatrix. (2022).

Bhogaraju, S. K., Ugolini, F., Belponer, F., Greci, A., & Elger, G. (n.d.). Reliability of Copper Sintered Interconnects under Extreme Thermal Shock Conditions. Technische Hochschule Ingolstadt & AMX Automatrix.

Maurizio Di Paolo Emilio. Sic Technology: Materials, Manufacturing, Devices and Design for Power Conversion (2024) ed.Springer